Description

The idea of making jigs and fixtures for the table saw is always one that creates a lot of debate. Some people insist that they are not worth it and “just do it by hand,” while other people love coming up with intricate fixtures that do a specific job really well. Bob’s approach is somewhere in the middle- will the jig be useful enough to be used over & over again, and is it better than one that is easily purchased?

The idea of making jigs and fixtures for the table saw is always one that creates a lot of debate. Some people insist that they are not worth it and “just do it by hand,” while other people love coming up with intricate fixtures that do a specific job really well. Bob’s approach is somewhere in the middle- will the jig be useful enough to be used over & over again, and is it better than one that is easily purchased?

This class is NOT a beginning table saw class. Participants must have some working experience with table saws & routers.

Note: Because of the jigs designs, you must have a table saw with a Biessemeyer-type fence. Bench-top or “Job-site” saws will not work with these jigs. Please specify the table saw make and model you have when registering for this class. If you have any questions, please contact Bob Van Dyke directly.

In this hands-on class, participants make several different jigs & fixtures for their table saw, all of which become staple tools in their shop.

Everyone goes home with several essential jigs for their table saw!

Table Saw Jigs

We start the week making a cross-cut sled. The accuracy and extra support this important fixture brings (almost) completely replace your table saw’ s stock miter gauge. Armed with the knowledge to make the sled, you surely go home and make more for cutting dados, wide panels, and specialized tasks.

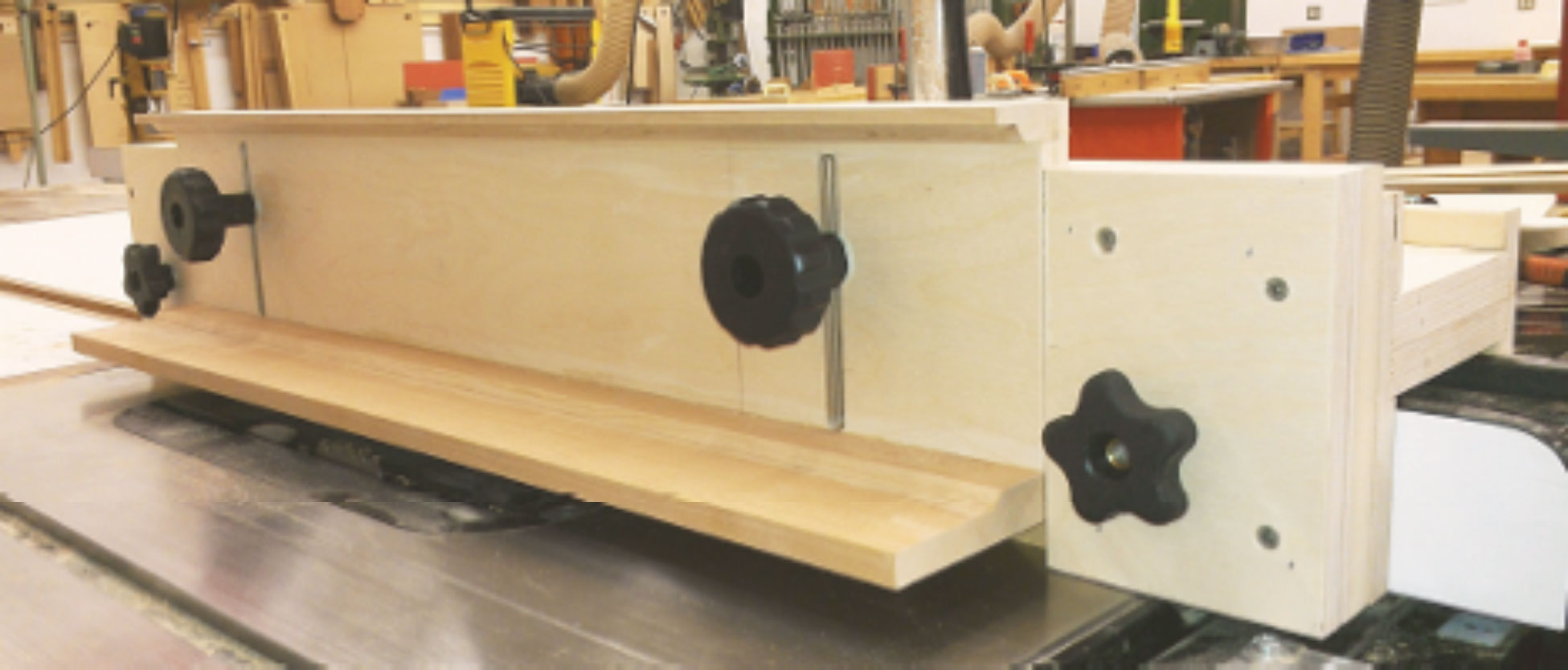

The next jig to be made is a tenoning jig – but this is not just any tenoning jig. This jig is designed for accuracy and versatility. Mass is what it is all about. This is one big jig, which means no vibration, and that translates to complete accuracy. The jig can also be fine-tuned to fit your table saw’s rip fence exactly. The jig’s size means that you can easily clamp large assemblies to it (think breadboard-end tabletops). Used in conjunction with two rip blades and a precisely made spacer, accurate tenons are a snap.

Additional Table Saw Jigs

The next two jigs were developed by Bob and are two of the most valuable table saw add-on jigs you can imagine! How many times have you clamped a sacrificial scrap of plywood to the fence to cut a rabbet and then had to move the clamps because they were in the way of the cut? And have you ever heard of pattern cutting on the table saw? The fixture we make is an ingenious and easily used base to fit over the existing table saw fence and allows you to bolt on any number of specialty fences quickly – certainly the most valuable is an easily adjusted and versatile “L” fence.

Any extra time during the class is devoted to making a series of small fixtures for the table saw: drop stops, sliding stops, hold-downs, and really simple feather-boards.

This is a class designed for people with solid experience on the table saw who can appreciate the value & importance of the jigs & fixtures you will be making.

Each student should supply his or her own:

- Safety glasses and hearing protection

- Combination or machinist square

- Bevel gauge

- Bench chisels

- Carvers mallet

- Dovetail saw

- Marking gauge

- Smooth plane or jack plane

- Block plane

- Tape measure or folding rule

If you do not have the tools on the list, don’t panic, there are plenty of tools for you to use in class.

Course Dates:

- May 1 – 5, 2023

Previous Class Dates:

- August 23 – 27, 2021

The shop opens at 8:30 am. Class begins at 9:00 am. A delicious lunch, snacks, and soft drinks are provided. Class ends at 4:30 pm – the shop remains open until 5:30 pm.

The class is limited to a maximum of 6 students.

Call or email to be placed on the waiting list if this class sells out.

Reviews

There are no reviews yet.